DAVOS, Switzerland and MUMBAI, India, Feb. 6, 2026 /PRNewswire/ — ACG Packaging Materials today announced that its Shirwal facility has been named a global Lighthouse and welcomed into the World Economic Forum’s (WEF) Lighthouse Network (GLN). This marks ACG’s second Lighthouse recognition, following its first in 2023 for the Pithampur capsules manufacturing facility. The distinction underscores ACG’s leadership in leveraging smart manufacturing to make medicines safer, sustainable, and more affordable globally.

Commenting on the recognition, Karan Singh, Managing Director, ACG said: “ACG has always believed that true leadership in the packaging sector comes from building smarter – not competing harder. Our Shirwal facility is now our second site to be recognised by the World Economic Forum’s Global Lighthouse Network, making ACG the world’s first pharmaceutical packaging company to receive this honour.”

He further added: “This achievement reflects the structures and frameworks we are putting in place across the Group. All ACG business entities are converging to optimise packaging so that medicines are safer, more sustainable, and more affordable. Repetition is the test of proof – in line with our ‘Make it Better’ commitment, we are replicating this Lighthouse excellence across our facilities and pioneering Sustainability Lighthouses for responsible, resilient manufacturing from India.”

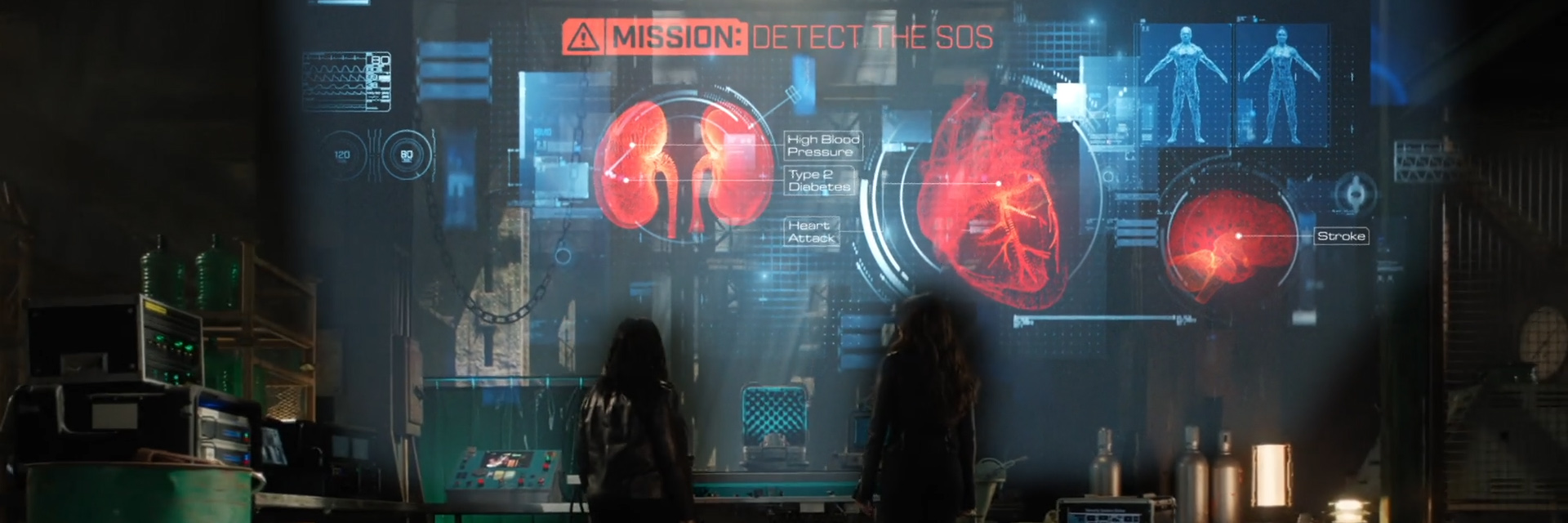

At Shirwal, the transformation programme spans end-to-end manufacturing operations and is enabled by generative AI, machine learning, deep learning, the Industrial Internet of Things (IIoT) and digital twin technologies. Operating in a highly competitive and increasingly commoditised pharmaceutical packaging market, the facility undertook a comprehensive digital transformation journey to boost productivity, agility and quality-while also reducing energy consumption and associated greenhouse gas emissions, and supporting a safer, more empowered workplace.

The programme has strengthened day-to-day decision-making by bringing greater visibility to operations and enabling faster, more consistent responses to variation across key manufacturing processes.

These initiatives have delivered measurable improvements, including:

- 40% reduction in lead times

- 71% reduction in defects

- 31% reduction in energy consumption

- 34% improvement in on-time delivery in full

Source link

Leave a Reply